News

2019-09-07

2019-09-07

Wood humidity - right values

Wood humidity - what is it? how to measure it? how much should it be? how does this affect the final product and its quality? how does it affect the durability of wooden joinery?

Wood humidity - this is the ratio of the weight of water contained in the wood to the weight of this wood. This ratio can be expressed in grams or as a percentage. Depending on the species of freshly cut tree, this value is between 50 and 150%. Relative humidity and absolute humidity are distinguished depending on the adopted reference point. Wood humidity depends on the conditions in which the wood is currently located and has a significant impact on the other properties of this material. The humidity is dependent on the thermal conductivity and apparent density of wood. Density is expressed in kilograms per cubic meter and is measured by the so-called air-dry wood, i.e. 15% humidity.

What should be the correct humidity of wood intended for the production of wooden joinery?

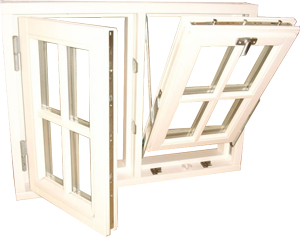

Of course, before the wood material supplied to the window joinery manufacturer becomes a wooden window, it requires numerous preparatory procedures. The raw material preparation process varies depending on the type of wood and its place of origin. The amount of wood species currently available is very large. We distinguish Asian wood windows referred to as the "common name" of "mahogany" or "meranti" wood, besides very popular (especially in Scandinavian countries) pine wood as well as larch, oak. These are the main types of wood intended for its manufacture and the most accessible to woodwork manufacturers. It is necessary to emphasize a very important fact - because windows and doors are not made of solid boards, which can be purchased in any sawmill and any type - the possibility of producing joinery depends on the availability of wooden sizing from a given type of wood. Any piece of furniture or decorative element made of wood can be made of any type of wood, having a piece of plank in hand and processing it, while wooden joinery will be made only of glued wood prepared by the producers of this glued material, prepared and glued in appropriate conditions. It is the type of this material available on the market that conditions the possibilities for woodwork manufacturers such as wood they offer to their customers. Hence, the most popular and available on the market are wood species (wooden sizing) such as: pine, meranti, sapeli, oak, larch.

The correct humidity of wood for elements installed inside rooms that will not come into contact with outside air, i.e. humidity of wood for stairs, furniture, floor or interior door is from 6 to 10%. For wooden elements that have constant contact with the outside air, i.e. windows or external doors, the wood humidity should be 12-14%.

Drying of the raw material is carried out by industrial methods in special dryers ensuring not only an elevated temperature (70-105 ° C), but also a circulating air circulation allowing the intensification of the process of water evaporation from wood. It is also necessary to protect the wood against rising humidity when using the finished window. It should be remembered that wood, whose humidity increases above 20%, exceeds the so-called "Dry protective state" and is exposed to aggression from fungi. It should also be remembered that in most cases, the presence of air is necessary for the development of wood-destroying microorganisms. In order to displace water and displace some air from the wood structure, it is impregnated.

What are the optimal conditions for wood processing?

Inside air that has less than 50% humidity behaves like a sponge that sucks water out of everything. At the moment when it changes - and it is different at night, during the day, in the morning, in the afternoon, before noon, in summer, in autumn - we are not able to predict what will happen with the production materials. The air humidification system ensures dimensional and shape stability of the processed material, reduces the consumption of paints, varnishes, solvents and reduces the electrostatic voltage, reduces the content of dust and dust in the air, reduces material losses (twisting and bending of elements, delamination, cracks - especially the ends of glued wood materials) ). The human factor is also important - with large differences in the level of humidity indoors and outdoors, the body reacts after some time. An employee who is sick is now a big problem for the employer. Theoretically, it can be replaced, but it is not always possible. All this generates additional costs.

It is recommended to work with wood in optimal conditions, in which the ambient temperature should oscillate between 18-20 ° C, wood humidity 12-14%, and relative humidity between 60 and 70%.

Adequate humidity in the paint shop rooms not only increases safety, but also guarantees an ideal surface after applying the varnish. Air humidification eliminates the electrostatic voltage, which also reduces dust in the hall and allows you to put the perfect varnish or paint layer.

Polski

Polski Angielski

Angielski Niemiecki

Niemiecki